Get Inspired

Build the life you love. Learn more about fusioneering:

Posted on August 8, 2023 in AI Painter

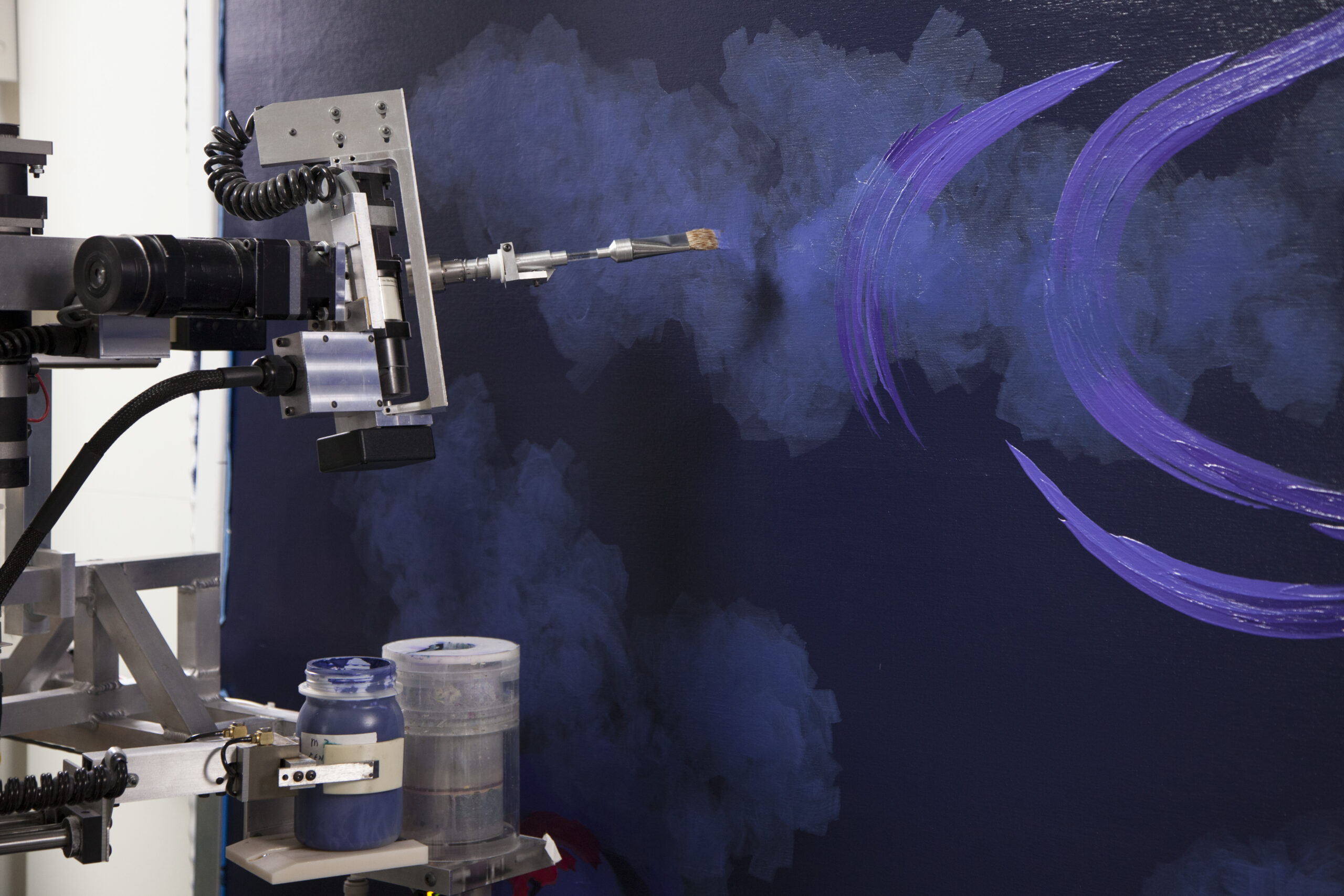

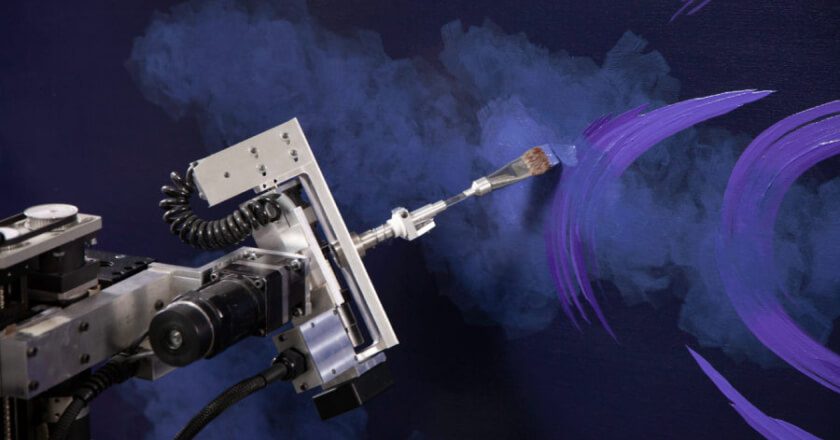

As long as artists have been using brushes to paint masterpieces, the cleaning of those brushes has proved a tedious and time-consuming bane. Even Dulcinea, modern inventor Paul Kirby’s masterful robot painter, had to overcome the hurdle of dirty brushes and brushes drying out from acrylic paint. Paul’s solution to the problem – using his trademark penchant for fusing art and technology – is just one of the many stunning innovations that sets this painting robot ahead of the competition.

Related: Watch Dulcinea in Action

Between 2001-2002, Paul and Dulcinea were having one of their most productive years ever. Dulcinea’s first two paintings had been a success – but Dulcinea was not yet a fully-automated painting machine. When standing at an easel, as Paul did in his years of art study while building Dulcinea, he never worried about cleaning his brush until the end of the day. So, he initially thought that as Dulcinea painted, and as she signaled him with a soft beep and message on the screen, he’d just wash the brush between colors and manually exchange jars of paint as needed. However, after Dulcinea’s first two paintings, Paul realized this manual approach was just not a satisfactory way of doing things going forward.

Ever the inventive fusioneer, Paul got to work inventing a solution.

Read More: Follow Along With Paul Kirby’s Inception of Dulcinea

Paul’s concept for an automatic brush washer had started taking shape. The idea was to build a “vertical car wash” consisting of twenty jets of water pointing down into the middle of a cylindrical container. Dulcinea uses acrylic paints, so washing with pressurized water seemed like a reasonable idea. The washer was roughly the size of a half-gallon of milk. A paintbrush would be inserted into an opening at the top and move up and down through the streams of water. Paul built the washer and then set up a test area on saw horses in the back of his workshop and used manual control valves for the water and a simple bucket to catch dirty water. The cylindrical device worked as intended.

After his success in cleaning test brushes, Paul mounted it on Dulcinea just below the wrist and automated the entire washing process with software controls. Clean water was piped 80’ from the utility room water supply to the back side of Dulcinea’s wall and then piped for another 50’ up and around Dulcinea’s cable carriers to the washer apparatus mounted just below the wrist. Dirty water was then pumped back the 50’ and another 80′ distance all the way back to the drainage area in the utility room. Everything should have worked like a charm.

But, when Dulcinea used her new brush washer… paint was still deep within the bristles.

Paul jokes he then “cried for two days.” More innovations were needed.

Related: The Challenges of Designing Dulcinea

When Paul manually tested brushes in the washer, he was only dipping the brushes into the paint. However, when the brushes were used in real painting conditions, paint was being worked deep within the bristles that the washer wasn’t capable of removing. To solve the problem, Paul needed to boil it down. He did this by asking himself how he, Paul the man – not Dulcinea the robot – would solve the issue of the dirty brushes. To remove the paint deep with the bristles, Paul would swish a brush around the bottom of his industrial sink. Then, he would need to reshape the brush with his hands to reform the bristles. Now – how could a robot imitate that?

Paul constructed a four-legged plastic stool with a corrugated seat on top that sat inside the vertical brush washing cylinder. The automation sequence would flood the washer with water to about an inch above the seat of the stool. Then, the robot would take the brush and squish it up, down, and twist it around against the corrugated plastic stool seat, massaging out the deeply set-in paint. This was followed by a final up/down rinsing cycle in the middle of the jets of water. In her software, Dulcinea knew the identification number of each brush and its corresponding bristle length, allowing it to calculate how far down to push and squish each brush’s bristles to properly clean them without causing harm.

The system worked, but another problem arose – after leaving the washer, the brushes were still wet with excess water, which caused Dulcinea’s subsequent brushstrokes to drip dirty water and paint down the canvas.

Through the collaborative work between Paul and Dulcinea, the robot’s brushwork naturally evolved, as did the increased size of her brushes for ever larger and more challenging paintings. This saw a necessary progression of solutions to fix the issue of excess water in the bristles. In the system’s first iteration, after the wash sequence, the bristles were pulled up against the edge of the round opening at the top of the washer. This effectively squeezed out the excess water and simultaneously reshaped the brush. This worked well for the initial, smaller brush.

Next, Dulcinea was given a new toy – a medium size brush. A “V” shape wedge was cut into the side of the round opening at the top of the brush washer. The brush was drawn upward through the V-shaped notch, wedging the bristles together and squeezing water out. The bristles were then pulled up again against the round edge of the opening to reshape them again. This worked well for medium-sized paint brushes.

Finally, with the newest and largest brushes, a blow-drying system was needed to ensure even these largest brushes could be adequately dried by the automated system. Some fine-tuning was needed, as brushes had to leave the blow-drying sequence dry enough to not drip water down the canvas, and yet damp enough for the bristles to again be reshaped using the V groove and the side of the circular opening. With the addition of the blow-dry system, Dulcinea’s fully automated brush washer was complete. The whole process of cleaning a brush takes only a couple minutes and uses very little water. The brushes are cleaned and reshaped, just as an artist would do.

The goal of full automation for Dulcinea was the ability to paint for many hours uninterrupted, or even overnight. Well, when acrylic paint dries, just like your house paint, the brush’s bristles get really stiff. So the automated brush washer has this added “secret” benefit. After each brush washing a timer is reset for twenty-five minutes. If a washing hasn’t occurred in that time span, then a new washing is initiated, thus ensuring the bristles will always be fresh and ready for the next brushstrokes.

Dulcinea currently knows roughly nine different brush shapes and sizes and how to best clean them without any outside intervention. The entire brush washing sequence is fully autonomous. When the washer is initially turned on there is a sensor to detect if water is available. If the system has been sitting idle for a while and there is no water immediately present, it primes the water line and then proceeds. During the washing process, another sensor detects if dirty water is present at the bottom of the brush washer and activates the pump until all dirty water has been removed, then the pump is turned off.

The novel solution of Dulcinea’s brush washer truly sets the robot apart, as it – along with the paint jar handling & sealing systems – allows Dulcinea to complete her entire painting workflow unassisted by human hands. It’s this kind of next-level thinking that has elevated Dulcinea from an AI-assisted painter to a fully-automated work of art in her own right.

Ready to see where Dulcinea is headed next? Stay tuned-in with The Kirby Foundation Instagram, Facebook, Pinterest, and email newsletter.

Want to see Dulcinea in action? Check out the inspiring short documentary film, Brushstroke.

Are you interested in hearing the complete story of Paul and Dulcinea? Watch the video (nominated for Best Short Film at the 2021 Vail and Portland Film Festivals) for more info.

Want to be the first to know about every exciting new project at the Kirby Foundation?

Join Our Mailing ListBuild the life you love. Learn more about fusioneering:

Why pick which passion you should follow? Fusioneering allows you to cultivate many interests into something innovative and revolutionary.

Meet Paul and explore how blending your interests can empower you to follow your enthusiasm and bring your passions to life.